Supermaterials are man-made versions of materials or substances that exist in nature where additional desirable properties are added or those that are common are enhanced. .

Throughout history man has made supermaterials. Some of the most well-known was turning iron into steel and petroleum into plastic sometimes using a bench grinder polishing wheel.

Today’s supermaterials continue to stretch and reform civilization. As our quest for faster, stronger and smaller continues unabated we are finding that the materials nature has presented us with simply cannot meet our needs and there must be modifications and advancements applied to many of them so that they can help to push us into new eras. Today’s supermaterials include graphene, which was derived from the same graphite that pencils. Graphene is developed in sheets just one atom thick, making it essentially a two-dimensional material. While is weighs next to nothing, it is up to 300 times stronger than steel. It also conducts electricity more efficiently and dissipates heat faster than any other known material. Finally, it is the only substance on earth that is completely impermeable by gas. Science is still figuring out the many uses for graphene but some of its recognized uses include: as lightweight protective armor, bendable display screens and vehicle batteries that can go 500 miles on a charge.

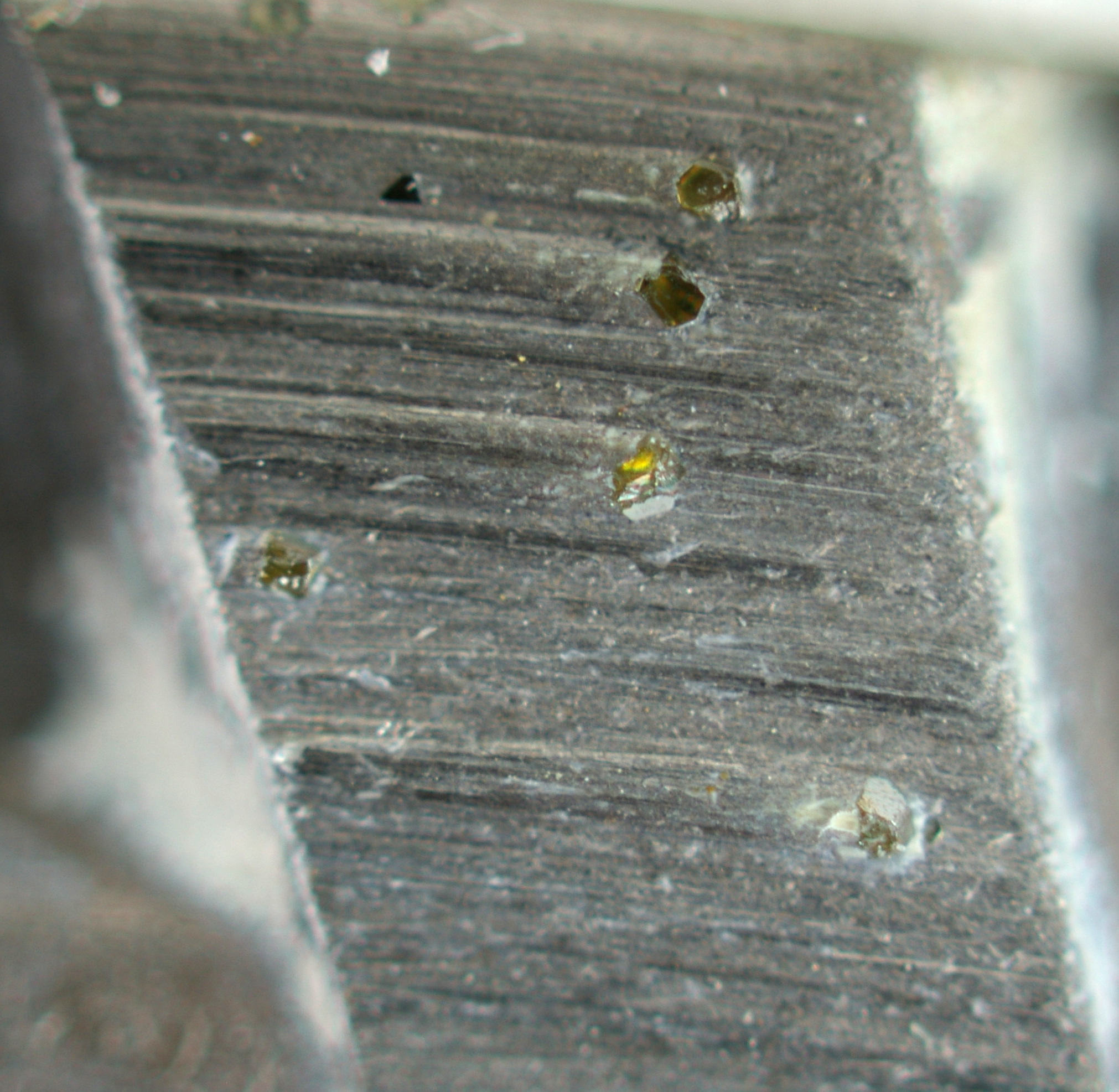

Supermaterials are used across industries with many currently being at the backbone of several. One great example is synthetic diamonds that are produced in an artificial process by high technology companies like Element Six. The specific properties of a synthetic diamond depend on the details of the manufacturing process. Some synthetic diamonds have properties such as hardness, thermal conductivity and electron mobility that are superior to those of natural diamonds.

As a result synthetic diamonds are ideal for applications in many industries.

Optics and Thermal

Because of the high temperatures and constant heat created within these industries, they rely heavily on materials that can dissipate and conduct heat efficiently Too much heat can create poor performance and device failure. Synthetic diamonds are used to create diamond heat spreaders that reduce heat considerably and allow devices to operate more powerfully for longer and on a smaller scale.

One particular use of synthetic diamonds is with high power laser optics. Synthetic diamonds never needs replacing, ensuring consistent productivity and constant performance, they will also minimise maintenance and downtime in devices they are used. Their key benefits are a lower running cost, and in comparison to other optical materials, they give a much higher performance to cost ratio.

Construction and Stone

Construction materials today are harder and more weather resistant than ever and newer materials are pushing this limit. To drill into or cut through these materials takes even harder materials and synthetic diamonds are fulfilling this need. They excel at providing the levels of hardness needed. Materials including granite and slate are great examples of these very hard stones that require special cutting tools. Synthetic diamonds are excellent at cutting, polishing and drilling these and other hard stones. This is often done with synthetic diamond equipped diamond saws that are tough.

Aerospace

The aerospace industry is one of the most advanced in the world and is constantly on the lookout for new materials from which to build aircraft. The focus is on materials that can reduce weight, and increase fuel economy.

The latest generation of aircraft is built primarily from Carbon Fibre Reinforced Plastic (CFRP) composites, which are lightweight and incredibly strong materials. CFRP is a fantastic material except that is extremely difficult to machine, challenging current machining methods. Drill bits laced with synthetic diamonds have superior wear resistance and strong edge toughness and can cut through tough fibres cleanly. The use of these supermaterials within the production, development and operation of modern-day aircraft means consumers are able to enjoy safer, more cost-effective flights as equipment becomes more reliable, precision becomes higher and manufacturing costs diminish.#UltimateSupermaterial